-

Posts

2,248 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by 11Budlite

-

I know the Duratec could be different, but for my Sigma-powered car it's a little bit louder but I never measured the difference. To me it sounds better, but it is still not close to the loudest car that I run with on track. No problems passing any of the sound limits at the tracks I frequent.

-

MassTuning is now running 4 different groups: Novice, Intermediate, Advanced, and Expert. They allow ride alongs in Intermediate and above.

-

I'm scheduled to be there with my Caterham. I think my son and our friend Tom will be there with their Exocets too.

-

When I switched to the race wingstays (P/N 76101, 76102) with Hoosier R7's this past winter, there was almost no clearance and I'm sure they would have rubbed at the first corner. I was able to bend the wingstays to gain enough clearance that they didn't rub at all at my first track day. I had to bend the arm in two places on each arm of the wingstay. The first bend was to get the clearance to the sidewall of the tire, and the second was to bring the upper portion of the arm parallel to the tire tread. After the first bend, I had to shim between the tire and the arm to maintain the sidewall clearance. It might be an option for you but YMMV.

-

Thanks Croc

-

I couldn't find anything else stamped or etched in the housing.

-

I finally got around to this. My blue rack has this P/N stamped on the housing near the pinion: B9905029. I did a lock to lock measurement and it looks like it's just under 2 turns. I put a protracter on the photos and estimated it at 1.88 turns L2L. Total rack movement L2L looks to be right at 4.0".

-

I'm pretty sure he meant using the same 'user' name on BaT that you use on USA7's. I use '11Budlite' on pretty much every online Forum that I frequent.

-

Thanks guys, when I get a chance I'll do the lock to lock rotation check to compare.

-

The video doesn't feature a Seven, but there is a yellow Seven belonging to a member here at the 32 second mark. I think they only made 30 of these but I bet they're fun:

-

It took a little research but I believe this is the car owned by Bob and Mary Kansa out of Ohio. Forum name: 'southwind25'. I know when I saw it they kept it REALLY clean:

-

Club is my favorite track in New England, absolutely beautiful and a lot of fun. Just got back from a 2-day event at Canaan, had a blast!

-

I'm pretty sure I know this car, but I could be wrong. It looks like the car owned by a couple from Ohio that I met back in 2008 at Carlisle.

-

A photo of your dash and the type of Seven you have would help. I'm assuming it's a Caterham but I think there were other brands that offered a carbon dash.

-

There's a phone number for Tom Carlin on this page: https://birkindirect-usa.com/pre-owned/

-

-

The mount spacing on the black rack of my 310 S3 is the same 7-3/4". I'm leaving for a NH track day so didn't want to mess with the toe to compare the total width.

-

I'm not sure. The total width is 39-7/8" without the outer tie rods, and the mount spacing is 7-3/4". I won't have access to my Caterham until tomorrow to compare.

-

Sold for $8500! https://bringatrailer.com/listing/engine-139/

-

My 2019 310 has a black painted Caterham rack and pinion. Does anyone know what the difference is on a blue painted Caterham rack like this one?

-

Thanks Graham, that makes a lot more sense.

-

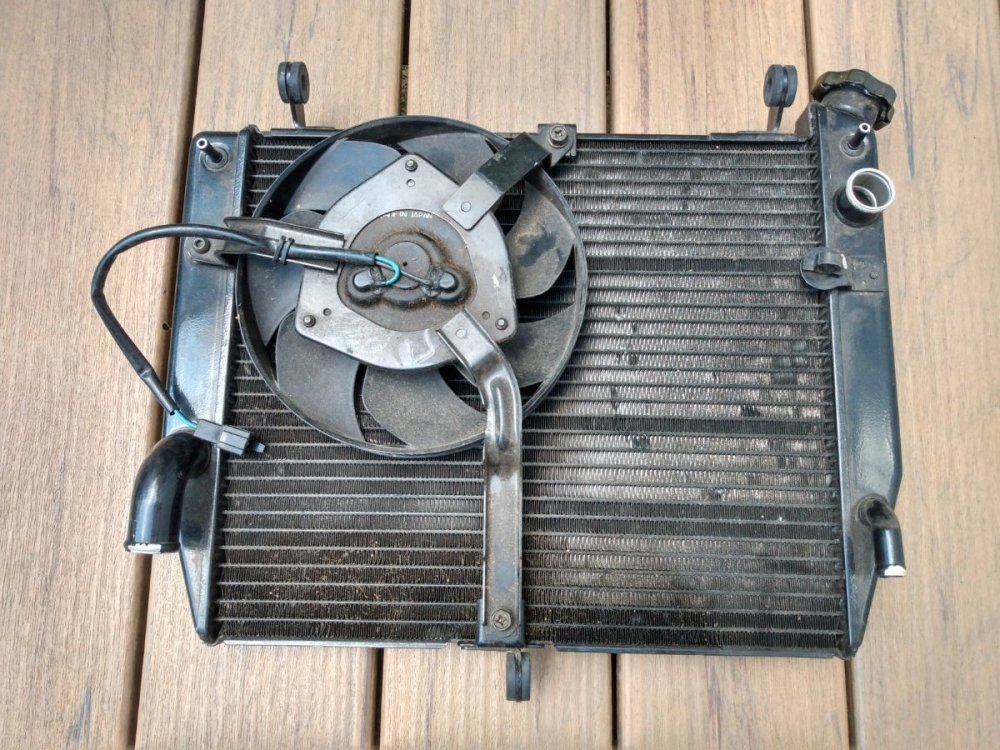

This radiator was with a group of Lotus/Caterham parts I just purchased. The core/tanks measure 42cm x 30cm. There are the two main inlet and outlets that measure 25mm, two smaller fittings that measure appr 6mm, and one unknown fitting at the bottom that measures appr 14mm. There are two upper mounts and one lower mount. There is a 20cm cooling fan that is 'Made in Japan'. Any idea what vehicle this could be from?

-

If you're not planning on tracking your car it's probably not as important to go to 13" wheels. My 2001 Birkin originally came with some TSW wheels with 195/50-15 tires mounted. I changed over to 15 x 7" Enkei RPF1's with 205/50-15 Falken Azenis and went from around 38 lbs to 30 lbs per corner. Made a big difference.