-

Posts

2,093 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by IamScotticus

-

consider the metallurgy of the fasteners...shear points and all. you might want to make sure your lifting bolts and hardware are grade 8 at least. you don't want an oh sh1t moment

-

I just want to know about Marine day?

-

I will dump my notes on the subject here. These are all from various sources, not my material. SifBronze No. 2 from Weldability Sif U.K. Arch has been using the gas jet flux braze welding process since the 1950s. The Lotus Seven at Anglo Canadian BRONZE WELDING RODS By William Fayers In Uncategorized March 31, 2021 10 Min read BRONZE WELDING RODS SUITABLE FOR REPAIRS TO YOUR LOTUS submit your comments or input here Nickel Bronze Brazing Rod. Contemplating some minor chassis frame repairs to my Lotus Seven Series 3, I decided to investigate the availability of suitable nickel bronze brazing rod to complete the repairs. In January 2014, I commenced a search of the web for suitable sites regarding Nickel Bronze Welding. I found a forum whereby contributors were asking questions and receiving good advice regarding bronze welding on Formula Ford and other sports racing cars manufactured in the U.K. The name of Calor Bronzecraft No.3 cropped up a few times. One contributor noted that it was now unavailable (2011 post), but that it was the rod of choice for Lotus, Arch Motors, and a number of other U.K. manufacturers of sports road and racing cars until its demise. I already had a good article on braze welding written by Bill Steagall, who had kindly forwarded a copy to me. It has been published in a couple of Lotus club magazines, describing how to braze weld with nickel bronze rod using a jet fluxer. Bill had also added a postscript advising that Calor Bronzecraft No. 3 was unavailable since writing his original article. I found the Murex Company (U.K.) web site, and at the time of writing (March 2014) Murex still had the specifications of their “Saffire” Nickel Bronze rod (10% nickel content) displayed on their site. An email reply from the Murex Technical Section advised that Murex had ‘moved on’ from gas welding products, and their line of braze welding rods and associated fluxes were no longer available. A rod called SifBronze No. 2 (from Weldability Sif U.K.) was highly recommended by a few of the forum contributors. These included an ex-Arch employee now living in New Zealand who still prefers a jet fluxer for braze welding, and a U.S. auto repair shop specializing in sports racing car repairs, likewise using a jet fluxer. I have recently been in contact with Bruce Robinson at Arch Motors and although he is a busy man, he kindly took the time to answer a few questions regarding their history with Lotus. Bruce advised that Arch has been using the gas jet flux braze welding process since the 1950s. They initially manufactured wishbones, brackets, pedals etc., for Lotus, and in January 1968 commenced construction of the Lotus Seven Series 2 chassis frame and associated parts. This was followed by the remainder of the Seven line (Series 3 and 4 cars), as well as Formula Ford chassis for Lotus and other constructors. Colin Chapman fully approved of the braze welding process for tubular chassis frame construction. Bruce noted that since the demise of Calor Bronzecraft rod, Arch now use SifBronze No.101, which is specifically formulated for use with the jet flux process. No.101 is a manganese/silicon bronze rod with no nickel content (according to the specification sheet on their web site), and has an ultimate tensile strength of 66717 p.s.i. (converted from the Newton/mm2 on the spec. sheet). For anyone interested in seeing how this product flows, please see the ‘YouTube’ videos “Ariel Atom Bronze Welding”; “Bronze Welding V8 Ariel Atom”; and “Bronze Welding” all by an excellent welder – Brian Ashcroft, using jet flux equipment and SifBronze No.101 rod. Brian Ashcroft advised me of the following: “I have used the Sif No.2 and it does weld very similar to No.101, it just doesn’t run quite as nicely. We found that No.2, although having a higher ultimate tensile strength, did tend to be more brittle than 101 which is why we prefer 101. I haven’t come across a weld failure with 101 yet in my 18 years of using it” (Note: Michael Costin and David Phipps allude to nickel bronze or manganese bronze welding in their book “Racing and Sports Car Chassis Design” published by Robert Bentley Inc.).

-

who happens to have a gas fluxer on hand!!!

-

The problem you might encounter with MIG/TIG on an area that has other gas welded joints is the the electricity may ruin any gas welds connected to the area. A trained eye can spot the difference.

-

Valve cover tightening sequence and torque values.

IamScotticus replied to geoz3's topic in General Tech

a smear of axle grease on the bottom will help keep oil in. -

Valve cover tightening sequence and torque values.

IamScotticus replied to geoz3's topic in General Tech

I don't know Pintos well, but in general, yes, aftermarket VCs usually can use OEM gaskets. Cork gaskets may have tabs on the sides that might need removal. Check out Walsh for Pinto action https://racerwalsh.com/ -

A grease can break down and liquify with heat and time. My grease gun with a tube in it did just that, leaked out and made a mess of the bucket it was in.

-

Valve cover tightening sequence and torque values.

IamScotticus replied to geoz3's topic in General Tech

Its not a critical value, its as tight as needed. Light smear of oil resistant RTV silicone sealant between the VC and gasket so it sticks to the cover when removed. Consider the VC an item that is periodically removed for valve lash checks and adjustments, so keep it easy to remove as needed. What makes gaskets leak is over tightening because the compression and heat dries out the material and it hardens. When the engine surfaces expand and contract the gaps open up to leak. Hand tight on those and watch it. -

Was it a product of the 21 program?

-

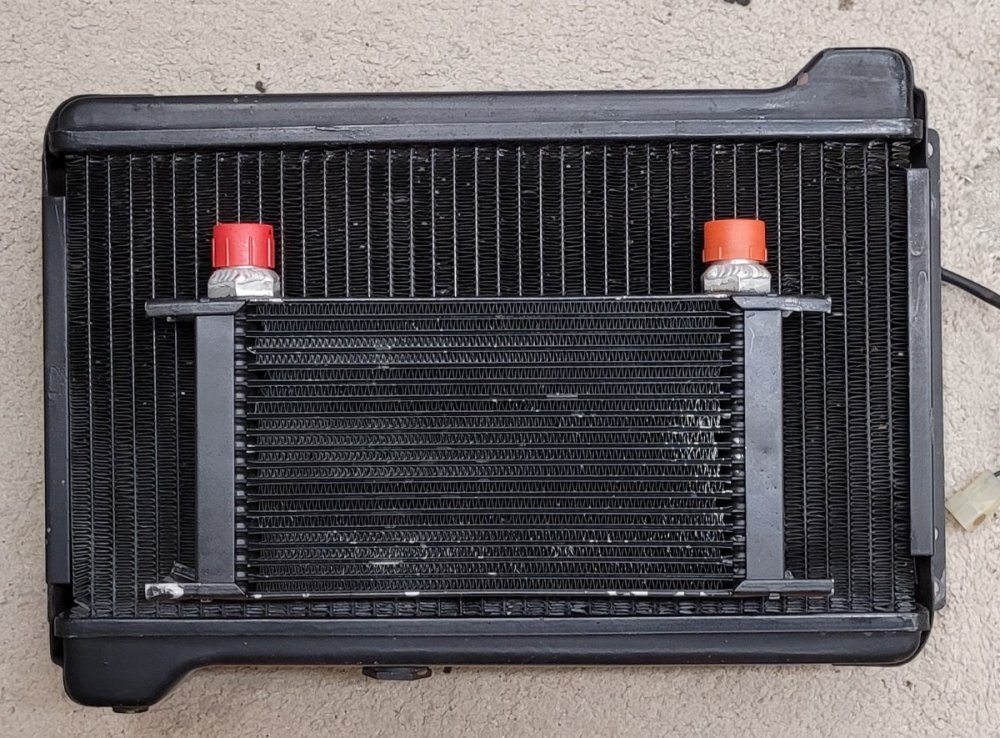

Thanks for the pics everyone! @Vovchandr Ive seen that radiator on csts before, is that standard Cat issue?

-

@inchoate do you have a fan back there too?

-

All good points. The necessity is something i contemplate.. As for location, I haven't seen OCs mouted anywhere else on 7s.

-

I have this Setrab 6" oil cooler. is it too big to go in front of this radiator? Radiator has a puller fan on back.

-

I see a lot of grime Its amazing what a cleaning and fresh grease can do.

-

Noooo! Not my thread!

-

Taking the engine out is a rite of passage. The clutch will eventually need service. The next best thing would be almost removing the whole engine, with disconnecting prop shaft, cooling, speedo and anything necessary, unbolt mounts and remove rear mount, lift engine with a crane just off the mounts, rsaise the rear of the car up until you can access the tail housing. Nope. Just pull it out. Remember to catch oil that will pour out the tail. This is a good opportunity to refresh and check many things early in your ownership. Believe it ir not, the transmission seals and clutch could have a much shorter life in a 1200 lb whip than a full size sled. Clutch wear, flywheel surface, transmission input and output sals, rear engine seals, mounts. All these can be refreshed and balanced ensuring you have a nice long ride. Welcome to Sevening! You are now chief engineer and pit crew for a race car!

-

Hi David. Beautiful car. What engine and transmission do you have?

-

Should the steering rack (or coupler) be separated for this?

-

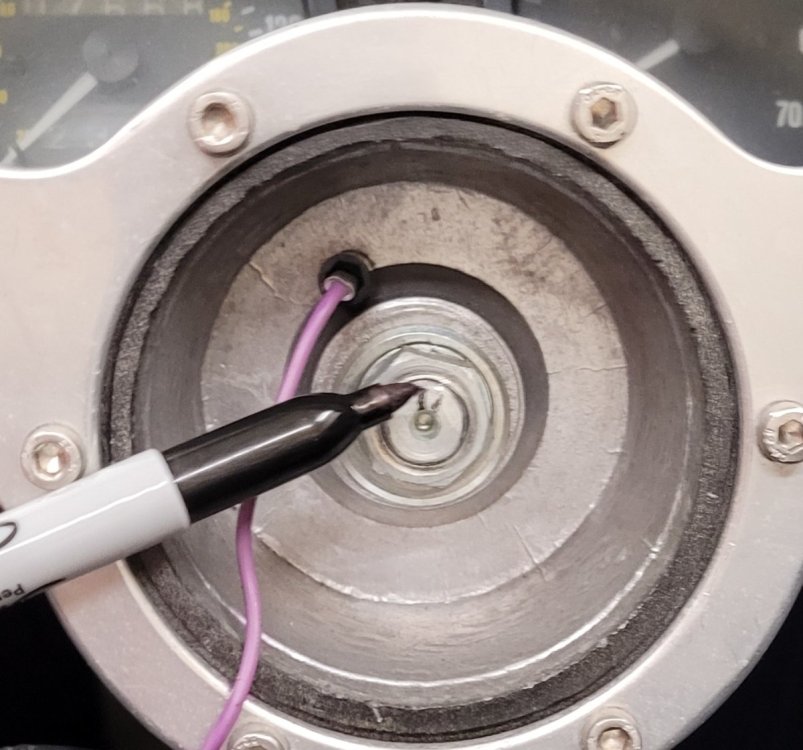

Honestly, my wheel might have come off with some persuasion. But my wheel had been off previously in the last ten years and I know I didn't over tighten it. I made this tutorial for those out there having more difficulty.

-

Ok For those with the ubiquitous Mountney GT wheeel, here is how I pulled mine and believe it or not, I didn't break anything! I don't think this needs much explanation but heres a few points to keep in mind: * Be aware of the location of the horn contact on the back, if you care about it, it could get damaged. * My claw was a very tight fit next to the speedo bezel. Too much of an angle and it could get damaged. Ensure the claw is fully seated don't let it ride out as you tighten the puller. * Precautionary stuff: SAFETY! Save your coils, DISCONNECT BATTERY. You will want to release the steering lock to do this, thus engaging the electrics. If your horn button is live, you could short something in the removal of the centre plate. * Tape is your friend. use it everywhere. * Sharpie marker to record the index location of the wheel. This may change after alignment so consider how tight you put this back together before alignment. * Once turning the puller, the hub loosened in about a half turn, easy. * The collumn nut is a lock nut that took a 3/4" socket. NEVER REUSE A LOCK NUT. I measured the thread at 1/2x20 SAE. But I haven't been able to chase with a regular nut to confirm it. No, I didn't use any lube. IMPORTANT: Always replace a lock nut with a new one, don't reuse a lock nut. I had previously removed my horn contact ring so that wasn't in the way. I got out my horn ring and I believe there is enough clearance for the claws to grip the rim.

-

Probably have a six bolt Mountney GT? The hub will be an aluminum alloy that may have corroded to the shaft. In which case a puller will be required. I am having difficulty removing my wiper arms and read on L7C that the spindles are pot metal and known to corrode and seize to the arms. That seems to be what's happening to me so I assume it could happen to the steering hub. Puller. Ive been wanting to get mine off as well so lets see if any of my articulated pullers do the job tomorrow.

-

Back in the game! And a (probably stupid) question.

IamScotticus replied to Saudio's topic in General Sevens Discussion

Is that a kir car? -

Back in the game! And a (probably stupid) question.

IamScotticus replied to Saudio's topic in General Sevens Discussion

Hijack alert: The question of why the 7th mark was reserved for a later designation is a good one worthy of a new thread. Perhaps the Austin 7 has something to do with it. As you all know, the early trials cars Colin built that led to the Mk6, were Austin 7 based. Perhaps the 7 was reserved for a successor to the 6, a trials influenced body of similar construction, which describes the 7 well. We can say the origin of the Lotus 7 is the Austin 7. -

No, I might reuse one for a header tank overflow catch, but the other catches and reservoirs will be fancy racing stuff riveted to something. Not a fan of where Cat chose to mount some of those bottles. Might use one for a screen washer bottle with a manual push button jet pump. Eliminate another wire circuit and switch.