-

Posts

2,297 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by MV8

-

I like them. With roller rockers and flat tappets (solid lifters), top end restrictors can greatly reduce the volume in the heads. The restrictors screw into the back of the block replacing the small plugs, reducing flow to the lifters and push rods. I assume you are scavenging from the back of each head and the valley (through the intake) with a total of three scavenge stages.

-

Opposite side intake is a given. I think Scott was thinking there may have been more than one design hood/bonnet offered but I don't believe so. I'd enjoy seeing the carnage repaired/altered step by step if you'd like to have a build topic. Whatever you do with, thanks for keeping it out of the crusher. Anything you do to it is better than that.

-

Duh! Here I am talking about crusty pipe when Mcmaster has spacers to order: https://www.mcmaster.com/spacers/for-screw-size~m8/for-screw-size~m10/ Look at the od of the flat area around the bolt holes in the alt to determine an acceptable spacer wall thickness. If not available, consider a washer between the alt body and the spacer or you can buy tube to cut to length. The alt bolt heads should be forward of the alt with split lock washers and regular washer between the heads and the alt body. The nuts can be tacked to the rear of the plate so they do not need to be held with a wrench to remove the alt. By putting the bolt heads forward, the alt need only move forward an inch or so for removal.

-

Thanks for sharing that. Very clean and looks great. It MIGHT be ok. Allow me to explain. Are there any numbers on the hose? This type of hose is called "push loc" and great for oil lines, carburetion, and most '80s GM TBI injection where working pressure will always be less than 50 psi and comparable to SAE30R6. Here is a push loc fuel hose source with info. It's likely most retailers are selling the same hoses: https://www.jegs.com/p/JEGS/JEGS-Push-Loc-Fuel-Hose/9277744/10002/-1 A typical 80-90s EFI system is right at the limit of the safe working pressure for R6 which is why they have R9 specifically for EFI and rated for a working pressure of 100 psi. Modified EFI systems can see up to 80 psi with fuel system mods (such as an FMU) for boosted applications. Newer systems may have higher pressures NA or boosted. I've not had a reason to keep up with that. Burst strength is always much higher but that testing is on new, perfect hose in controlled conditions. The push loc working pressure limit of 50 psi may have more to do with the hose to fitting connection than the hose. I don't know.

-

-

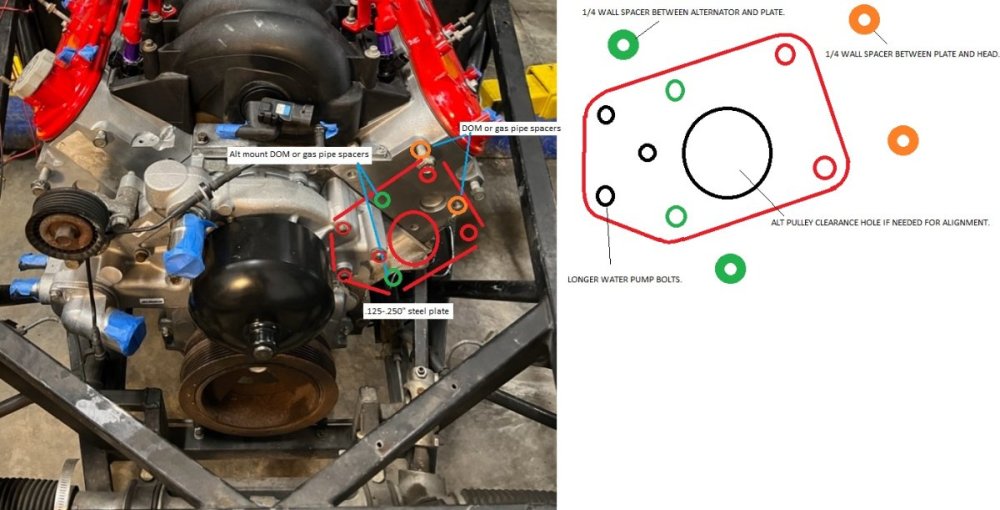

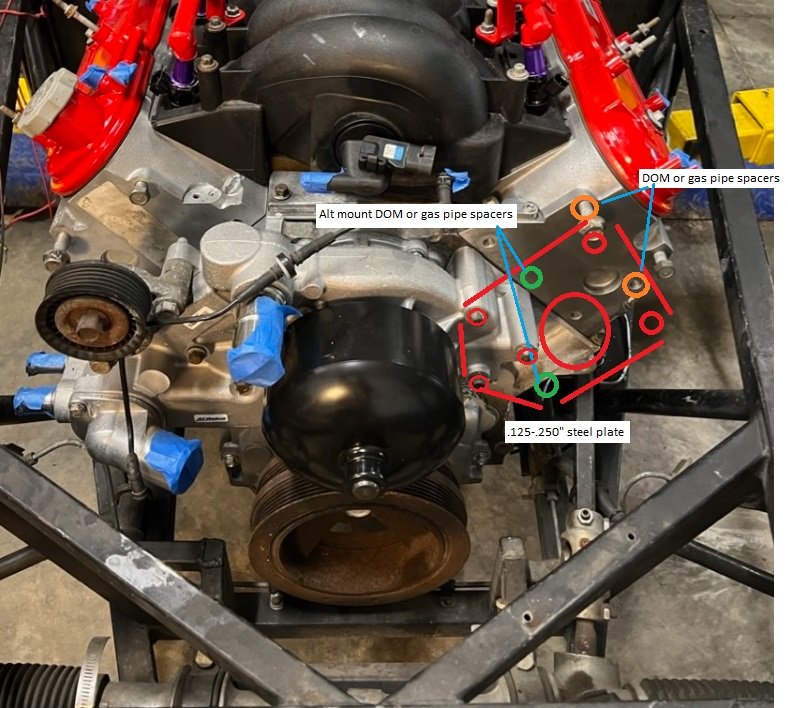

For the m8 alt bolts, you could use dom tube (5/8, 0.148 wall) or 1/4 gas pipe. For the m10 head bolts, dom tube 3/4, 0.165 wall. For a close fit to the head bolts, you might have to rotary file or ream slightly depending on the dom/pipe and bolt tolerances, dom 5/8, 0.120 wall or 1/4 gas pipe. The pipe has a weld ridge inside that is easily filed down. DOM is drawn over a mandrel to flatten the inside weld bead. You can find short pieces of dom offered on ebay if your local metal supplier doesn't stock it. The fit to the tube spacers is not critical. The holes in the plate align. The gas pipe is easy to find but needs more work (sanding inside and out, and filing the weld bead inside).

-

This should make it more clear. The spacers and plate can be low carbon mild steel or thick walled aluminum tube. The alternator is designed to be supported by just the material around the attachment bolts. There is no need to spread the load across the case. The water pump bolts should be a 1/4 inch longer. If you tell me the head bolt and alt bolt sizes, I can tell you what size pipe or dom to use. The placement of the alt on the plate is a guess based on the chassis clearance.

-

Maybe this will give you some ideas. Common steel plate and gas pipe or dom tube. No extra long studs. No welding. The pipe/dom needs to be cut or ground square though.

-

That is one way good way to do it. FWIW, the oem type dorman rail fitting is not for nylon tube but teflon lined rubber hose to slip on and clamp though it MIGHT be ok. Nylon requires a very tight fit since there is no clamp. It can be very difficult to insert a fitting into nylon without special tools. The reason they switch to hose at the end is for flexibilty for servicing. Nylon is too rigid and fragile by comparison. Also, one way to tell if a fitting barb is for nylon or hose is a nylon barb usually has at least three beads/ridges to seal the nylon where a hose barb has at least one barb and if two barbs, a wide enough gap between them for the clamp to squeeze between the barbs.

-

Based on what you want, I'd consider shelving the existing axle as-is and adapting a 90's or newer suzuki sidekick/geo tracker rear axle for several reasons. The pros: 1) The width should be close to what you need as-is. 2) The ring gear is a bit larger than the m68 for stronger gear sets (6.7" vs. 6.9") 3) This axle comes with 4.30, 4.62, 5.12 and 5.37:1 gear sets (4.62 strongest with the fewest ring teeth). 4) A torsen type diff is available for about $650. 5) Despite being considered weak for a 4x4 with very large od tires, it should be a little stronger/heavier than what you have. 6) The drop out diff carrier/pumpkin is easily setup on a bench. The con: The axle uses a very large, common 4x4 truck 5 bolt circle and hub but adapters are available. The adapters would increase the axle width about two inches. I have a 90s 2 door, 2wd convertible tracker I converted to an s10 v6 and 700r4 with an open 5.12 axle and 235-60-16 tires on grand vitara wheels. Let me know if you'd like any measurements. The 90's axle is a three link where the 99 and newer is a 4 link with a panhard bar, but you'd be cutting everything off to duplicate the birkin brackets. This is my installed axle and my 4.30 diff with a couple web pics of the axles.

-

You might want to post pics of the fuel lines at the firewall and the tunnel so we can see if they also could use some improvement for safety. I would hope to see either ford oem type black nylon or steel with supports at least every foot or so, three inches or less from any transition, and with minimal rubber hose and split loom guards as needed to prevent rubbing.

-

The housing ribs on top of the center section are unique to this axle but I agree, the cover is shaped a little differently for the datsun axles pictured. It may be different for the toyota van applications. I suspect there was some sort of trade agreement with Datsun and Toyota in order to sell their products in South Africa that was satisfied by locally sourced axles.

-

Based on the routing, it must be hose and not nylon semi-rigid line. You can use standard, efi high pressure hose of the appropriate size (likely 5/16 or 3/8"). Teflon lined would be better. The fittings appear fine but the barbs are likely a little different in size /mismatched. The silver clamp would be split with cutting pliers and removed with a flat blade screwdriver to spread and pliers. The brass fitting crimp sleeve can also be removed with more effort. Clamp in a vice to hold it, then use a hacksaw to diagonal cut the sleeve, spread with a flat blade screwdriver, then remove the sleeve with pliers and finally the hose. The brass barb needs to be close to the same size as the elbow barb. If not, it can probably be filed so the right size hose for the elbow fits properly on the brass barb. A direct replacement brass barb that fits the inf threads and is the right hose size may not be readily available but there are more options depending on what we see on that end of the hose.

-

Post a pic of the hose installed. It looks like a rail elbow fitting but I'd don't know what the brass end is attached to. It looks like the brass end and hose came from a tool.

-

You could just pop in a similar face cheap ebay gps speedo for now and cap the trans end. No noise, no cal, adds lightness, etc. Then you can spend as much time as you want on the old speedo and have the hole in the dash filled.

-

PM if you'd like to send me the hose for repair.

-

Lots of variables. A picture of a hose on a table can only narrow it down so far. Dorman and AGS make the fittings, nylon line, pinch clamps for teflon lined hose, and tools for repair. I suspect the hose id is too big for the elbow fitting and the possibly wrong type.

-

I think it would hard to find if it was ever available for such a small diff. Part of the problem is that as the numerical ratio increases, the thickness of the teeth decreases while at the same time the multiplied torque increases. You might consider an axle conversion to an equivalent that came with a 4.30 ratio (maximium), like the Toyota 10 bolt 6.7" ring gear axle used in dwarf cars, just not severely shortened on the right side. For a used axle, look at 82 and older corona, 84-87 corolla GTS, 74-79 SR5, 71-85 celica ST and GT. I expect there are parts available for these for racing. They came with either two or four spider gears and an open or limited slip. A Ford 8 inch is a common axle here that is built like the famous ford 9 inch only smaller and lighter. I think it was used in the H&S Seven.

-

I understand some tubes were cut. Here are some chassis pics in this link: https://www.caterhamlotus7.club/blogs/lotus-7-s4-rebuild-blog Here are some good pics (left-right scroll) of one for sale that might help assemble the puzzle: http://findclassicars.com/lotus/127680-1972-lotus-super-seven-7-s4-classic-british-roadster-track-car-not-a-replica.html Post if you are looking for anything specific.

-

https://www.teikokukikaku.com/en

-

Articles on the birkin mention a toyota axle and maybe they switched to that at some point. If you go to quaifes site, they list a diff under the caterham as a BW68 plus the ridges on top of the housing make it unique. Are you looking for a more highway friendly, numerically lower ratio?

-

Nice score Tom! We've been talking about that one on Locostusa. Did the seller have any other parts for sale off this car like the hard top and doors? Buy back whatever you can. I see you bought the trailer too. I'll see what I can find.

-

Lonnie posted to locostusa. Nice video.

-

I was thinking crack since you were talking about vibration, but you said pin hole. It sounds like the leak is between a tube and the end plate and a mfg defect versus a vibration issue.

-

Has it always read low? Calibration speed for most is 1000 rpm at the cable for a 60 mph indication. The plastic driven gear on the transmission end of the speedometer cable is usually where calibration to a good instrument is made. Each tooth is typically a 5 mph change. When gears to change the ratio are not available, a ratio changing box is used. The boxes and gears are universal and assembled to order. The box goes between two cables or direct attach to the transmission the same way the cable does. The sometimes include a 90 degree drive for clearance and better cable routing. Costs run $75-150. If it is a speedo issue, it sounds like the magnet has lost strength or there is too much friction. The adjustment you are referring to sounds like the end of the clock spring.