-

Posts

291 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by Dave W

-

Here some photos of my gas pedal and heel rest. The heel rest is not attached to the floor, but is just wedged into the foot well. I would mock up the heel rest location before fab'ing, because it needs to be located correctly within a 1/2" F/A. The gas pedal has an arched surface with the attaching gusset off centered on the back side, which allows you to flip the pedal to change the cross car location, plus you can use spacer between the pedal arm for added off set. The gusset also has three attaching holes for up/down adjustment. Plus you can pivot the pedal angle. I also have adjustable pedal stops, but they are attached to the frame that sets F/A. The design even has an adjustable cable eye, that allows some lever ratio changes by screw the eye up/down to change the cable travel. The "J" hook on the upper section is for the return spring. Note that my brake pedal is also adjustable, up/down and screws in and out to help position the pedal relative to the gas pedal. Dave W

-

Probably the easiest solution is to just weld or rivet a arced plate on to the current pedal. If you are good at fabrication, look at re-designing the pedal setup, that would allow you to adjust fore/aft, up/down, pedal angle, and cross car. A heel rest will also help. Last your shoes makes a big difference. I'm big believer of pedal adjustment. All my pedals are adjustable. If you like, I can post a photo of the throttle pedal and heel rest. Dave W

-

One vote for a loose ball joint. Get the grease gun out and see if greasing changes anything. Another option for the wheel bearing is to used safety wire, Vs a cotter pin. It's less than have the thickness and gives you more leeway on the castle nut position. Dave W

-

When you are adjusting, Is the wheel off the ground? I adjust the front wheel bearings be feel. After re-greasing and tightening the bearing down, I backed off the nut, then re-tighten the nut until there is a slight drag when you spin the wheel and NO PLAY. I would think you are better off with reduced play. [wheel bearings are cheap] The improvement in steering is worth the price of replacing the bearings after 40-50K miles. DaveW

-

Search for banjo bolt. Should make life easier. Dave W

-

Rich mixture indication [one plug]. Options: Add injection cleaner to the system, clean the one injector, replace injector. DaveW

-

Look at the very end of the stud. Several stab bar links have an Allen key socket in the stud, used to hold the stud from turning during installation. Dave W

-

Or you could try flat flooring, but you will need to level surface, i.e. you will have to shim the garage floor because the typical floor has to much slope. I was within 18 lbs. on the worst corner Vs actually corner Wt. To be honest I could not tell the difference, that the 18lbs. made in handling. Which ever method you use, you still need to level the floor. Mark the four spots on the floor and the shims needed at each location. That will save a lot of time for the next set-up. Dave W

-

Unless this a strictly racing build, the vibration is going to drive you crazy! Have you looked at adding a spacer(s) under one or both engine mounts? You have to be careful not to pre-load the engine mount(s) or trans mount. If that is not an option it's time for some heat and a ballpeen hammer. Dave W

-

Shifter assembly -- removed and reinstalled, feels sloppier.

Dave W replied to Driven's topic in General Sevens Discussion

Must transmissions will have a small nylon cup [some times brass] that the end of the gear shift lever will pilot into. Just search for replacement parts for the trans that you have. There should be an exploded view of the assembly. It should not be hard to find a replacement part, since it's a high wear item. Dave W -

A possible option for attaching your windage tray and using red Loctite, is to simple safety wire hex head bolts without a locking agent. Dave W

-

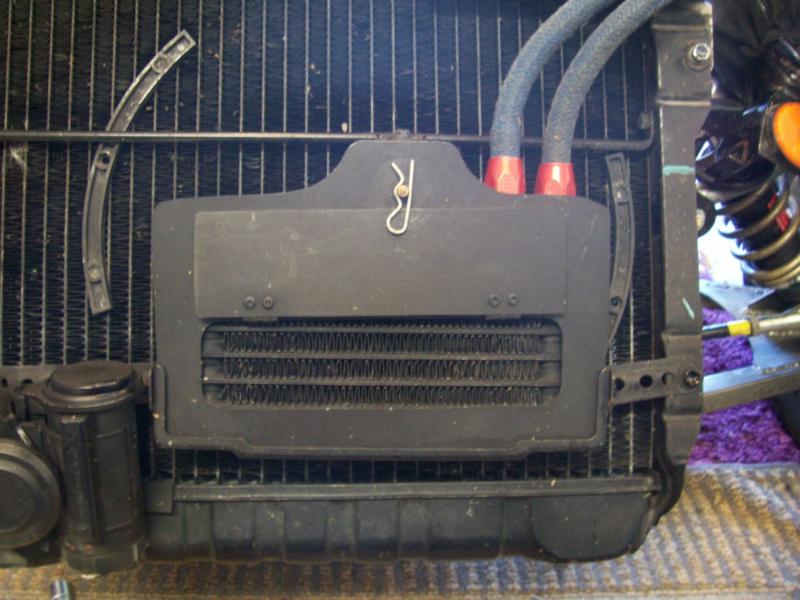

Replace or pull the thermostat and check the temp which it opens at with a pot off hot water on the stove. I had the same problem even after installing a 92C thermostat, but I'm dealing with lower temps. I have a large rad and at the time I did not have a thermal by-pass for the oil cooler. After adding a block off plate in front of the oil cooler, warm up time was cut to the 10-15 minute range. I now have a Mocal thermo by-pass on the oil cooler, which works great. Dave W

-

Lowered floor, Prescription Goggles et al.

Dave W replied to ottocycle's topic in General Sevens Discussion

I have a pair of safety goggles and use prescription glasses, but prefer to use safety slip-on side shields. The side shields do not restrict your vision as much as the goggles, and still give you protection across the top, side, and bottom. Plus they will slip in your shirt pocket when not in use. If looking for the side shields, you want the soft, not hard, plastic shields. Dave W -

Where in Michigan is the Seven located. DaveW

-

I added a new longer and larger Dia. 30" muffler, which was still way to loud! I finally extended the exhaust system all the way to the rear and then added a short aftermarket motorcycle muffler at the very end of the system. Much more liveable

-

If you are using that much gas, you should see exhaust smoke and smell raw gas. You could get better mileage with a BBC. I get 22 MPG on the back roads and 30 MPG at 75 on the expressway. Dave W

-

Wheel Cylinders For 1960, Series 1, Lotus 7 America

Dave W replied to lotsats's topic in General Tech

If the series 1 car is unmolested, it is a good chance that the rear live axle is from a Standard [Triumph] 10. DaveW -

Wheel Cylinders For 1960, Series 1, Lotus 7 America

Dave W replied to lotsats's topic in General Tech

Victoria British shows two Sprite/Midget rear wheel cylinders for 1958-62 M/Y's. Their P/N 7-406 or 7-315. Take a look at the break down view, to determine which type you need. They should probably be able to help on the Triumph Herald front cylinder stuff on their web pages. DaveW -

Victoria British has piston sets from std all the way to .060" over for the 948 engine. DaveW

-

If the diagram is correct? I would not think that having the temp sensor in the heater feed line would be ideal. I would verify the location of your temp sensor first. DaveW

-

Yupper we have metric threads!!! I do not understand that logic. 95% will use AN fittings on the tank, but we need a adaptors? DaveW

-

I would guess that all your fittings are on the tank are JIC i.e. AN, and that you need a 7/8-14 drain plug. A metric 20mm thread actually has a pitch of 2.5. I would 2nd the use of a drain plug with an o-ring or sealing washer. DaveW

-

You could add baffles around the upper sides and top of the rad to force all the air thru the rad. Also you may not have enough open spaces behind the rad to allow the air flow to easily exit the engine bay. Try a run with the hood off and see what effect it has on the running temp. DaveW

-

John There is an early American Seven here in South Lyon that has not been on the road for probably 10 yrs. I have not talked to the owner in in 2 or 3 years, but it might be for sale. It has the small BMC motor. I [or we] could check to see if they might want to part with the Seven. DaveW

-

I will actually drive my car if we have dry roads, may be 3 or 4 times during the winter. [i need a Seven fix!!] and yes I have a heater. I put the car in semi-storage. Tires 30+ psi, battery tender, full tank, and a car cover. But once a month, if it has not been on the road, I'll push it outside and run it for 15 minutes. I agree with inchoate, the biggest problem in the alky in the gas. DaveW