-

Posts

371 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by sf4018

-

The Aim Solo2DL with OBDII connector is gonna be the cheapest Aim option ($700) if you have to have GPS info tied to the data. You can get it to learn a custom route/track, I've never used that feature though. You'll need the MBE9A4 programming software to configure what data is sent out on CAN, then configure Aim to get it. The AiM software is Race Studio 3, you'll have to define a custom CAN protocol on it, it's not too hard. I can send you mine if you need a template. If you don't need the GPS, I would think your ECU software should have a built in data logger.

-

Track Day Prep - Side Impact Protection/etc

sf4018 replied to 11Budlite's topic in General Sevens Discussion

Something else to consider perhaps is some kind of fire suppression - some people use fire safety sticks that are close to hand somewhere in the cockpit, which would be pretty cheap and easy to install (and remove), though I can't say how effective they are in a real emergency. -

Track Day Prep - Side Impact Protection/etc

sf4018 replied to 11Budlite's topic in General Sevens Discussion

KitKat's track car roll cage has the best side impact protection that I've seen anyways, see link below to his pics. It has multiple support points along the length. -

It seems there are a few around your neck of the woods, I met a guy called Andrew who was working pit out at COTA - he has a Zetec S3, runs in one of the SCCA groups, I think he said his dad has one too. Super nice fella, even when charged with giving me a talk to for spinning out in the warm up session .

-

Thanks so much @sitous and @JohnCh for the pointers, I managed to get her running again and save the weekend. 🍻

-

You were on the right track, it’s a loose wire on the pump relay. I jiggle the relay around and I can hear it click and the pump goes on. Same if I wiggle the wires behind it. Just gotta figure out how to fix it in the field.

-

Another track day, another breakdown. All was good on track then fuel pump cut suddenly. Fuel pump has no electrical power, inertia switch is ok but has no power either, so it’s upstream of that. Fuses are all ok. ECU is bypassed so it’s not that. Everything else is functioning normally. Anyone have any ideas?

-

Exciting times, congrats on a great build!

-

Those are 4mm or 5/32” on mine

-

Should be Fastener Pack ZBC02. It doesn't give sizes on the pack sheet I have except for the rivet - 1/8" x 0.39". Nothing for the buttons and sockets.

-

Did the first ECU setup run with Steve of SBD Motorsports yesterday. A few relevant notes: 1. The ECU fuel pump run command signal can be programmed to run as long as the engine is turning over, which is safer than the "always on" mode that it's wired as right now (currently only killed by key turn out of position 2 or inertia switch trip). So electrically it would have been better to keep the fuel pump control relay and harness intact. I will re-install a new harness over the winter, but for the tracks days coming up next month it's gonna be fine. 2. Steve tuned the cold start perfectly, it fires up first time now. Awesome. 3. Idle and low speed tuning took several hours and apparently is the hardest part of the tune. He made some changes while I was driving around the neighborhood with the PC connected to the ECU with a desktop session to the UK via cell. It was really cool to see how even small changes to mapping can make a noticeable difference. If I can figure out how to tune it myself later on it'll be car nerd heaven.

-

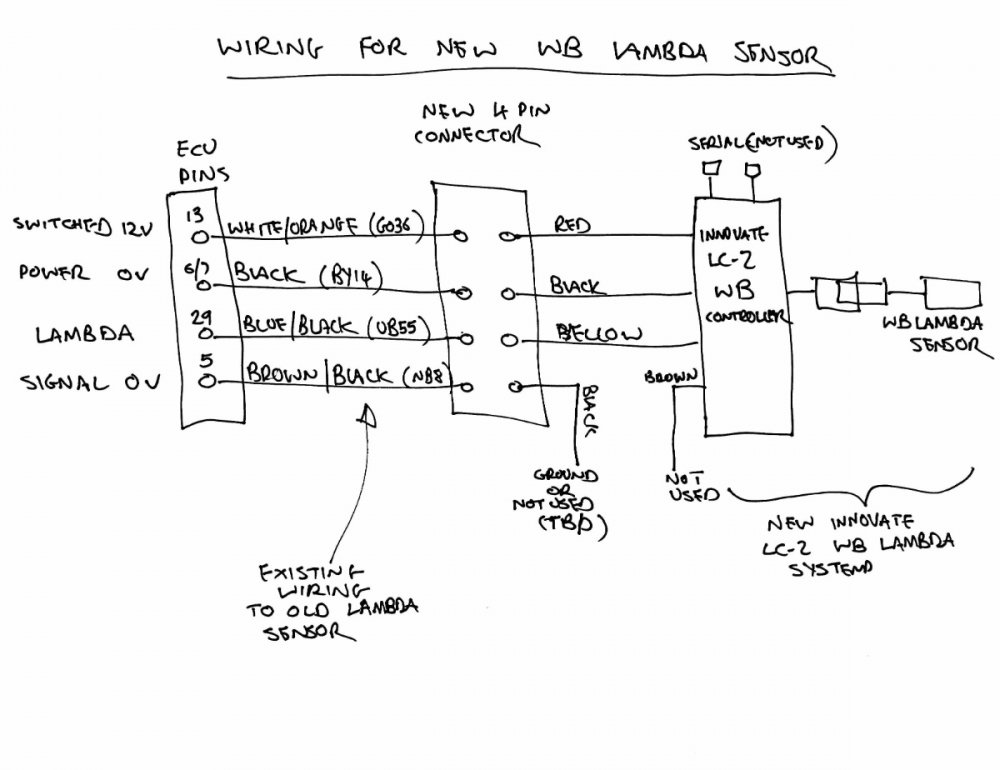

SBD Motorsports recommended replacing the stock lambda sensor with an Innovate LC-2 Wideband System, so I went with that. Mechanically it swaps out easily without modification. Electrically this is the plan… The only unknown is whether the signal 0V NB8 should be grounded (probably to the chassis). Looking at the Caterham schematics the NB8 signal ground wire is shared with several other sensors, plus it’s close to 0 ohms to battery ground already, so right now I’m going to lean not connecting it. Ground loops are not good.

-

Has anyone replaced a standard lambda sensor with a wideband one? I believe it's 6 wires but there's only 4 on the current sensor connector (brown/blue/black/white).

-

I believe so, I can pull up the raw O2 sensor value and lambda number on the ECU software, I’ll be able to send this to the Aim Solo2 for recording. Life is good with an unlocked ECU 🙂 Edit: Upon research it looks likely that it’s not a wideband lambda sensor, so I’m gonna replace it.

-

I only see 1 throttle body at the entrance to the manifold, everything past that seems static, but I don’t really know. That’s good info thanks! So I started up the engine cold a few times now, it reliably holds idle either the first or second attempt, so I don’t think it’s a temperature thing, maybe air bubbles in the line working it’s way out. Whatever the reason, it’s pretty good now. SBD Motorsport have been great so far, it’s so great to be able to send any data I want to the AIM system. They responded about the RPM meter not showing RPM correctly they said it was a setting for 4 pulses per cycle instead of 1, I’ll try that tonight. Just gotta do fine tuning after that. What a painful project, but the end result turned out pretty good. I appreciate all the help and support from everyone, it made a big difference! Thanks! Simon

-

I blipped the throttle to keep the engine going for a while, then after it warmed up some it held idle fine. I also experimented with the 2 electrical control variations for the pump. Here’s how the original on demand pump controlled by the ECU and pump control relay (same as original internal pump control) works… …the pump runs for a second to charge the pressure, then I start the engine, fails to hold idle, then the pump is re-activated by the ECU. How it ever worked before i don’t know. Fuel pressure was around 30psi. I know the plumbing isn’t setup for on demand but I wanted to see what happened. So the relay is now chopped off and ECU signals taped off. Next was running the pump full time by wiring YG154 and B10 to the pump… …holds about 52psi. Engine was cold, even with this higher pressure idle didn’t hold. So the electrical is sorted now. I’m gonna let the engine cool completely and see if it’s a cold start issue. If it is, which looks likely, I guess I’ll need help what to change in the ECU.

-

Moving on to the new ECU…it’s so nice to be able to go in and configure stuff. The RPM meter on the dash doesn’t work properly, it’s like it’s showing pressure or something, but I’ll figure that out later. The main issue right now is the engine doesn’t idle, anyone have a clue what could be the problem? Here’s a vid of the problem… https://youtube.com/shorts/u2HwIthDE-g?feature=share

-

XFlow randomly stops running, why and how to fix?

sf4018 replied to TexasDreamer's topic in General Tech

Does sound electrical, hopefully something simple and obvious like a loose ground wire. -

It was plumbed in by Caterham, there’s a handle on the dash. So I put 5 gallons in, set off the pump for a second but no gas flow or pressure. Maybe I have to put more fuel in or bleed it somehow?

-

-

Great video and excellent driving!

-

The new ECU is in, started the plumbing, starting at the engine and going back. 5/16” fuel line quick connect connector, 6AN hose clamp, 7.9mm stainless braided high temp fuel hose… Although the internet said to use hose clamps not cable ties for fuel lines I used the latter like the original installation, seems fine to use for the tunnel… For the exit point from the tunnel above the LSD I didn’t feel comfortable snaking around the hose like the old one because it’s quite a bit larger diameter and didn’t want to risk pinching it, so I cut a notch in the wood above the LSD to use as an exit point. It’s cut to the right a little to make room for the fire extinguisher on the left…

-

Minimum console height on SV with lowered floors

sf4018 replied to kayentaskier's topic in General Tech

317mm from the top to the lowered floor. Note that it’s not straight down, there is a ridge at the lowered floor section at least for mine. -

If the temp bumpers are expensive I would just go a scrapyard get some comically large bumpers like F150 for $20. They won’t be able to deny it just cos it looks stupid.