-

Posts

2,093 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by IamScotticus

-

Unfortunately, i didn't save any of the solids from the pump cleaning to use as test media. but there isn't any evidence of it in the block inlet water pump mounting face, where coolant did pool for years. is it possible that this concealment is in reaction to aluminum components only? The engine will get a flush, Im hoping to not have to go to the extent of a hot tank, yet. It will get tanked eventually for a dry sump galley tap. But for now, I just want to get running.

-

Gurus, Having sat for eleven years, psrtvof that time still holding the engine coolant, part drained, and at some point I may have mixed orange and green coolant, when I took the coolant pump off, I found the impeller chamber and hose inlet passage completely cloged with a hard waxy congealed goop. I did not see any on the engine side. Therefore, I am asking if it is necessary to hot tank the engine to remove any other blockages? I didn't see any goop in the radiator or lower hose, only similar corrosion and scaling in the aluminum upper coolant outlet thermostat housing. Is this corrosion and jelling only an aluminum thing, leaving the iron safe? I am planning to connect a pump and hose circuit to the upper and lower to circulate a rust removal solution in lieu of a dip.

-

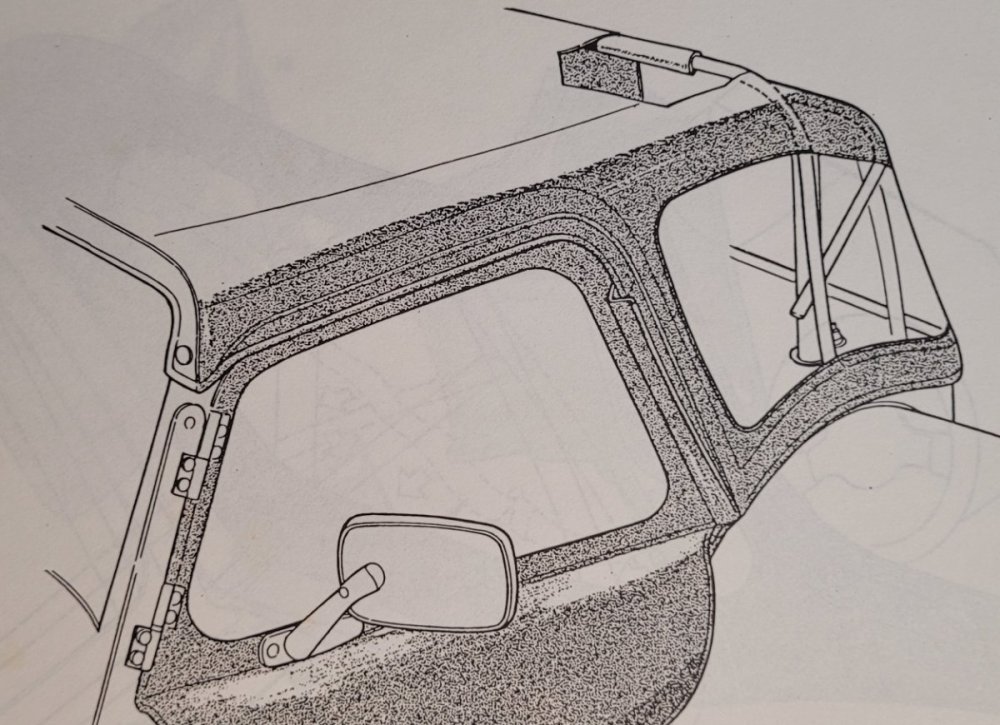

Thats gorgeous work! What's the square window?

-

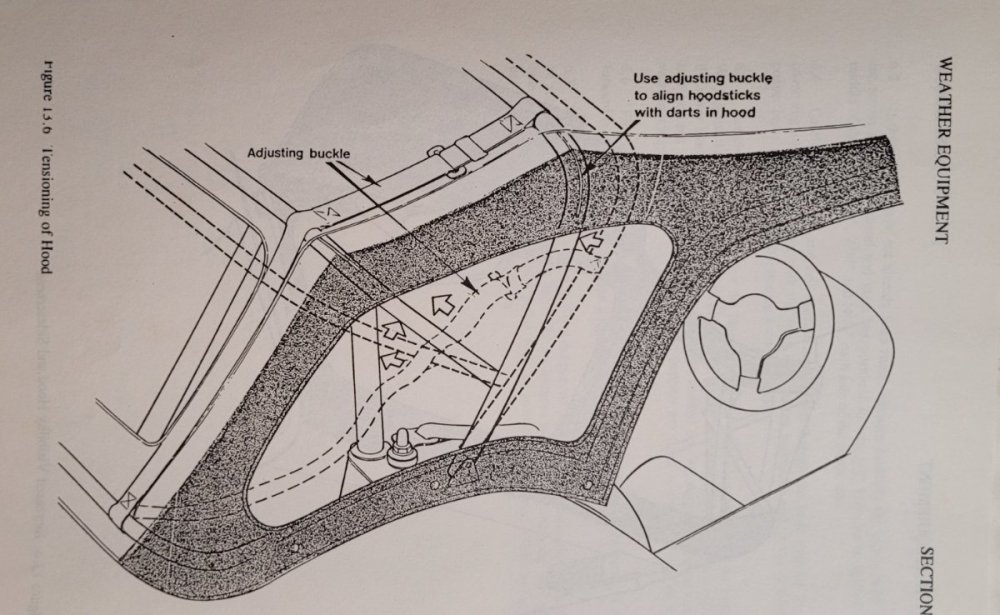

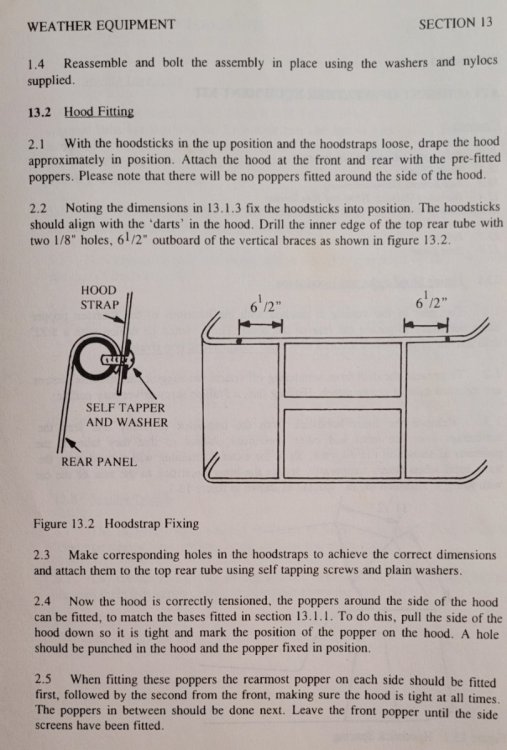

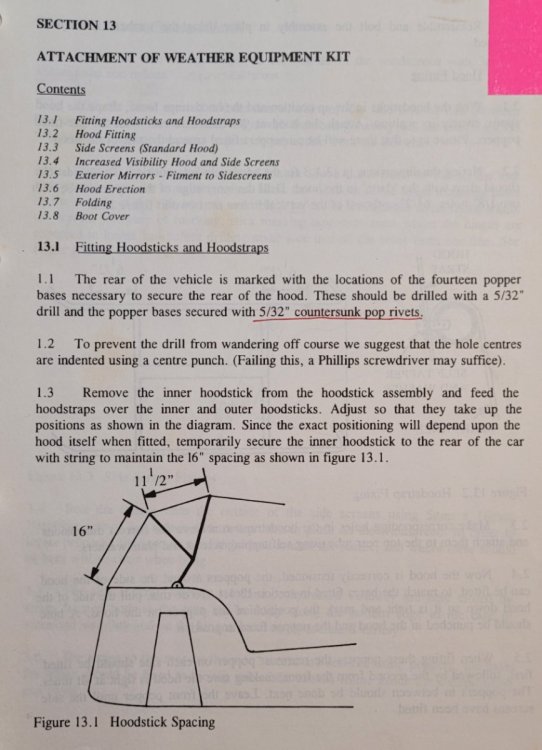

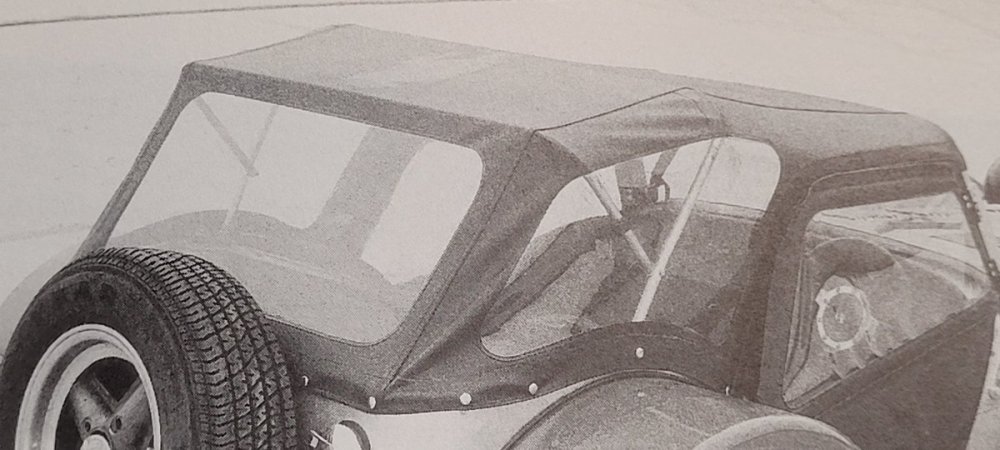

Many things on the 7 have been remarkably consistent through the years. The basket profile that dictates the hood stick height hasn't changed. Hood pleat locations for different stick positionings have been used to clear different rollover bars, like the FIA. In a measuring exercise with Des (NSXguy), I compared the lengths of a mid 80s Short cockpit to my mid 90s long, I found no great difference in length between the shock tower and the front Petty strut mount. Wherever Cat lengthened the cockpit, they must not have altered the frame. I think that you have a very good chance of a new hood and doors fitting, although a bit fiddly initially.

-

-

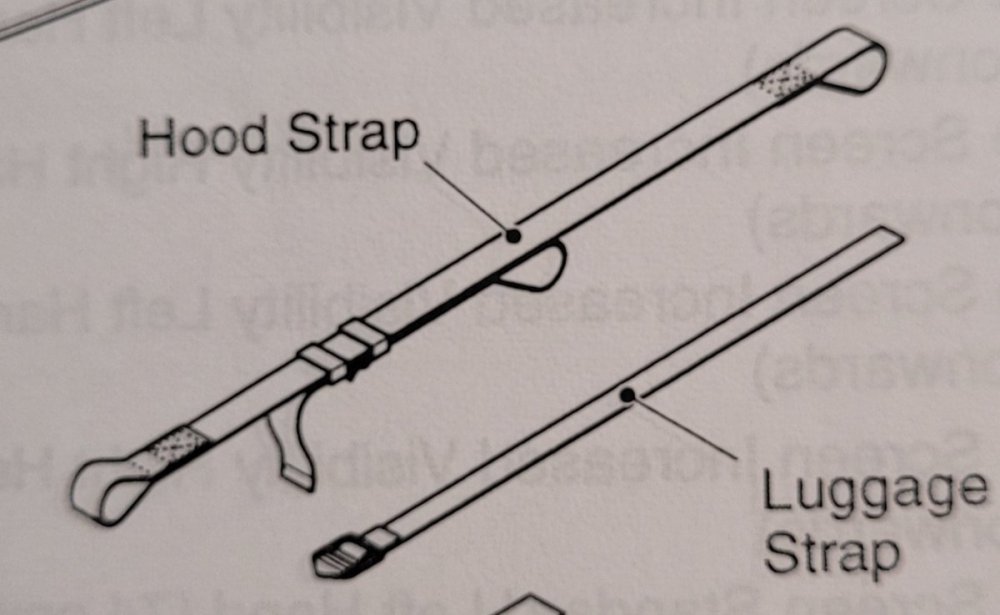

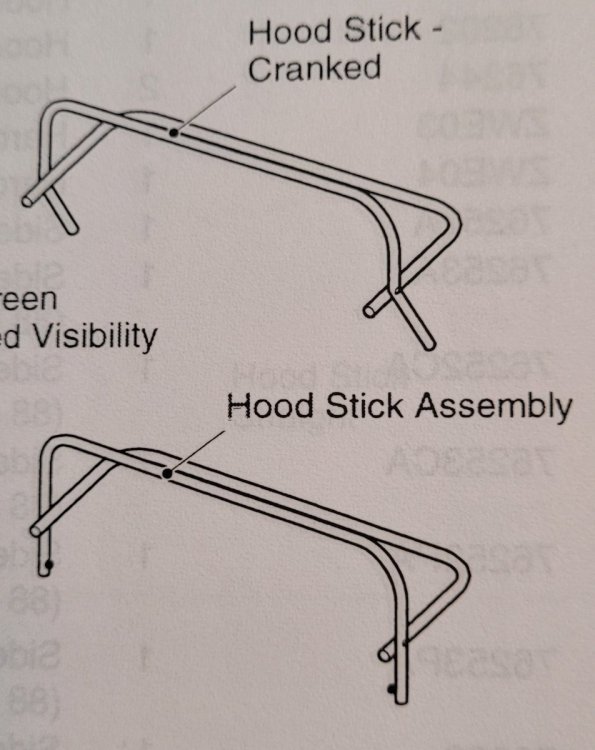

Bill, I have a set of hood sticks for you, aluminum and not drilled. The sticks may need a little persuasion on angle but they follow the basket tube perfectly. An issue may be how your hinge brackets are spaced, for sticks to mount inboard or outboard. These are bent for outboard. The alu inner tube is still long, needs to be cut to final length to clear the damper tops. The black sticks are Caterham. Both are 16mm dia. I would be honored if these found their way onto your car.

-

In general, the top tube is formed to the same shape as the top rear chassis basket, terminating at the hinge brackets. The inner, or rear support tube is formed to the inner cotour of the main, attatched with cross drilled hinge screws at some point. That point may not be determined in advance of hood fitting, as the construction of the hood may dictate that exact point to achieve proper tension. Probably best done inside the car. Please video the exercise for every to see!

-

I will go to my shed and measure those but someone else might get you that quicker. Im not too sure about stainless bending as well as aluminum.

-

-

I suspect they are there for standard road safety regulation compliance. Coat the screen with RainX and you won't need the wipers for rain. A splash of mud, yes, but not rain. Although I have seen RainX work on others vehicles, I have never really cared to coat my regular cars windshields with it because my wipers have been good. However, I would consider using it on the 7 as a contingent safety item in the event the wipers are insufficient. I couldn't find the OE source for the wipers, but I had read once they are Morris Mini, possibly. Regardless, locate the car those wipers were standard equipment on then ask around on the fan forums what alternatives they have found. A search turned up this https://www.caterhamlotus7.club/forum/techtalk/wiper-blades-4 someone suggested the equivalent wipers from Car Builder Solutions are good.

-

I have some duct tape for ya https://www.hobbylobby.com/Art-Supplies/Project-Supplies/Adhesive-Tape/Neon-Green-Art-Project-Tape/p/80985828 Found it at Hobby Lobby. Happy to send you a few rolls. PM

-

Interested as well...same situation. Due to limited (reasonable) variety of 13" I am wanting to try 14" wheels for a better rubber selection, and maybe better looking wheels, but not wanting 15". Since I am stuck with a Morris Ital 3.75" PCD, My options are fairly limited. I did find one thing, VTO wheels in Phoenix, AZ. They have a surprisingly generous selection of styles in stock and custom drillings. An example, this one in 14" +22mm offset althought 5.5 wide, is available in my PCD as a custom drilling. https://www.vtowheels.com/Retro-4-14-x-55-Custom-Drilled-22mm_p_110.html A Minilite style is available in 6". As for buying a set of unknown brand name, and questionable quality, I wouldn't be too concerned about it, they should be adequate in a 1,200 pound car. Just keep the pressures at 20psi and don't push the road holding limits into under/over steer.

-

so clean....

-

-

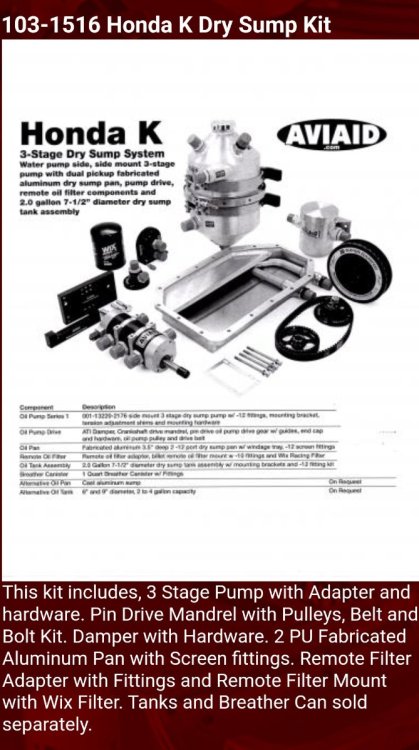

Its hard to argue with a Mazda transmission, the availability and adaptability... After reading up on the Honda K, it too appears to be a very adaptable and sporting engine. It comes down to how much support there is for the components. The K is very popular now, not lacking anything.

-

My first experience in a 7 was in Peter Fawcett's orange S4 in Dallas. I was working at an inspection & oil change garage when Peter's son Andrew pulled in for a sticker. I got to take it for the required brake test drive. I had to fail it on a faulty turn signal, so he had to come back. On the return, Peter brought the car and he graciously invited me to come by the house to see the Loti collection. The S4 is now in the hands of Andrew's wife, a regular at Texas Motorsport Ranch, I believe.

-

Hey, why is the air scoop on the left?

-

Those wheels are awesome

-

will want to separate the shell from the frame to inspect for rust. ground up rustoration.

-

The RX7 GSL is a favorite

-

I had that car by Anson. S2 1500 with Caterham paint, oversized Minilites, BDR seats, functional steering, live axle. You were lucky to find one with the windscreen fitted properly. They claimed to be 1:18 scale but the Ansons were much larger than the Kyoshos, which were more accurate. The Anson is probably the largest 7 diecast available besides the Kyosho 1:12 BDR, which isn't Diecast but real aluminum panels attached to a plastic space frame. I had to remove my Anson's seats and steering wheel and over spray them in black, an obvious detail Im surprised the diorama build omitted. Plenty of these cars on Ebay

-

Getting closer to a purchase. More questions.

IamScotticus replied to Saudio's topic in General Sevens Discussion

And, whis practical about a 7?