-

Posts

2,297 -

Joined

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by MV8

-

If it's stiff, I'm thinking dry and rusty inside which can cause it to orbit versus spin true, so yes. Since it is such a pain to access, you might consider having it checked for true and balanced at a machine shop or driveline shop. It may never have been straight to begin with. I'm guessing it was never greased since it is a 2018 model.

-

Funny/bad kit locost chassis repairs (though they could just as easily been "repairs" to a cat). https://www.youtube.com/watch?v=rPplHdJt0G8

-

You should have an obd2 port to plug in a reader to check and clear stored codes. I think auto parts stores will do this for free. Disconnecting power resets the "learning" process but codes are stored until cleared. If you had an 04 or newer, just replacing the sensor would require an alignment adjustment. If you had not run the engine without the sensor in place (no-choice because it fell off while running), no code would have been set and it would run the same.

-

I think it is slightly too old to require an alignment. It could be the ecu set a code thinking it was something other than parts falling off. Disconnect the battery for 5 minutes, reconnect and see if you have the same issue. No first hand exp with these.

-

I've seen tools like that but I think it will be a nightmare to use in that tunnel. If the engine is out, pulling the trans forward a foot should be easy. Just unbolt the mount to the chassis, pull off the shift lever and boot, unbolt the slave, and slide it forward enough to bring the shaft out the front. You could cut a couple boards to sit across the chassis rails to support the trans in the engine bay if needed, so no need to lift it out also. It is a good idea to crayon marks on the slip yoke, pinion flange coupler, and the weld yokes on the tube so they go back together the same way. Easy job with a bench vise and the right od sockets (one much bigger socket to force one bearing cap out of the yoke and another to push the bearing cap in from the other side at the same time in the vice.

-

From your pic, assuming the driveshaft is still coupled to the diff, it looks like your slip yoke is bottomed into the trans. I can't say for cats, but standard practice for IRS and live axle is the installed driveshaft length puts the slip yoke about 3/4 inch from bottoming in the trans. This allows the driveshaft to be uncoupled from the pinion flange and slide forward to clear the pinion nut and with a live axle, prevent damage from bottoming with axle suspension travel. Most cats I've seen have the tunnel fully boxed so if the clearance exists, it may still be impossible to remove the driveshaft with the diff mounted. You might try just unbolting the diff and sliding it rearward and lifting it up. Hard to tell from you pic. After replacing the joints, if the joints feel notchy when rotating the ends, one or more needle bearing were left out during assembly.

-

Lithium is the most common grease used for both prop joints and wheel bearings but not good for cv joints (extreme pressure with moly-disulphide added such as flat tappet cam break in lube) . Historically, calcium base was for the chassis for waterproofing and sodium base was for higher temps. I use common, synthetic name brand lithium for chassis lube, ujoints, and wheel bearing packing. There are many kinds of lithium grease so make sure it is labelled for wheel bearings to use for the ujoints. If there is a grease fitting, it should be on the center cross body or have a fitting in the center of one of the caps. Sometimes, there is no fitting. Ujoints are standardized and cheap. Replacements usually come with a fitting.

-

Yes, only race clutches in 7.25". A standard size traditional flywheel and clutch are much better since you are eliminating the boost. It looks like you will need a custom made manifold or reuse all or most of the stainless primary tubes and a custom made slip-on collector to make the side pipe transition. Good custom work usually requires the car to be present as each pipe is fitted to the space available. What you have is the Lotus twin cam "big valve" head with a round two bolt port instead of the more common cosworth square two and four bolt configs. This looks to be the right flange but would not be a side pipe config: https://www.motorsport-tools.com/simpson-lotus-cortina-exhaust-manifold-twin-cam-2-25-stainless-steel.html The turbo acted as a muffler so you will probably want to fit a muffler/silencer. You may want to fit a side pipe available for newer models that has everything you want. Whomever is building the exhaust can build the side pipe to fit.

-

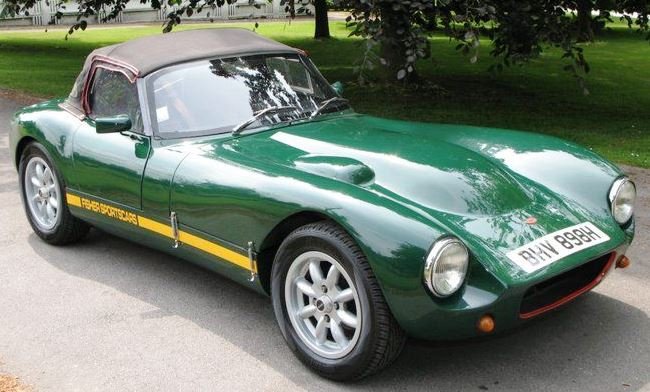

I thought about ginetta but that is actually an early/classic fisher fury. Id' thought about just bringing the body and top over, making the rest here with parts more common here or maybe an ebay UK find without drivetrain, so essentially just parts. https://www.furysportscars.com/

-

I guess the import cost is the same if it is a kit car project (where the paperwork is of little use for titling here as a donor) or a grey market production vehicle. I like the Fisher Fury, Riot, etc. I could go deaf when trying to drive on the wrong side of the road (all that screaming about what's coming head-on). Wrong side of the car, not so much.

-

About the grounding, a 1/2 inch long #10 or 1/4 sheet metal screw can be ok for one or two 18ga wires if the powder coat is removed under the head. To extend the length of time between cleaning, use dielectric grease between or a spray sealer over the connection. For more or thicker wires, 1/4-20 riv nut, riv stud, drill a nearby existing bracket, weld or fit a plate across a corner or off a tube with two or more screws to hang a stud that can accept a cluster of ring terminals, a buss bar, terminal strip with a shorting bar, etc. The schematics give you an idea of where the ground junctions would be on the miata. On the caterham (and a lot of other older cars), instead of junction blocks, they stagger the splices over a foot of wire.

-

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

Kidding aside (don't call France just yet), a chip-less key does not mean you do not have pats. You can have a key and transceiver in the dash for the ecu to work and also a chip-less key that does everything else a key would do without a pats ecu. If you traced the wires in the schematic I provided a while back, you might find a pats module and key inside the dash. -

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

Well, the "guys" are never wrong so I guess you are back to square one. Check with France. -

computer for 2002 thru 2004 Ford 4cy fuel injected SVT

MV8 replied to HUTCH's topic in General Sevens Discussion

If "the guys" had "nothing like it", how would they know what is on the vehicle? If you cannot determine if the car has pats on your own (ecu installed or not), the car needs to go to someone who can. -

I don't know the torque spec. I'd simply "snug" it. A liquid sealant would not seal oily threads very well. I expect it has a reusable sealing washer like the typical engine oil drain plug. Use a 1/4 inch drive or stubby 3/8 and you'll probably won't over-tighten the plugs. There is no pressure behind the plug. It doesn't need to be very tight. Some interesting problems with the 2015 and older cat with the bmw application titan diff and carbon faced clutch plates: https://www.international7network.org/post/bmw-limited-slip-differential-a-titan-ic-problem

-

Look for a black plug in the side of the sump toward the rear with an offset tab and a small screw to one side holding it in. It is sealed by an o-ring. Pulls straight out with a small screw driver under the tab to wedge it out. This is a scavenge return screen. I assume you mean the LS version of the oil that includes the friction modifier for the diff clutches. Since this is the only oil specified, and it isn't due to be changed, you might want to stick with that, but any same weight GL5 synthetic for use with a friction modifier should be ok.

-

That's how I'd lower the front, but only if I could get the trans down the same amount to keep the same (but lower) relationship to the pinion and front and rear joint angles that are slightly greater but still cancel. If they had added a 1/4 inch somewhere (1/8 to the cowl/bonnet, an 1/8 to the vertical rails) I don't think anybody would cry foul for ruining the lines. Could be tolerances from one chassis to the next.

-

If you drive on normal, bump, poor roads, I'd just try a slightly bigger front bar and leave the spring rates as-is, expecting it may shift the handling toward understeering. Keep the old parts just in case you want to go back. A bar would be more effective since the springs don't compress much in a couple degrees of roll, so the rate change would need to be much higher (living with the downsides) to match a small change in bar od. The bar is a better tool for roll either way. Front rates can fine tune over/understeer. Rear rates are enough to prevent bottoming. If you can't find the spring rate info, the rate can be determined without removal using a dial caliper for the actual od (versus advertised 2.5") and the wire thickness (may need to lift to spread the spring to get the caliper tips in there far enough to measure), and how many coils have any gap at ride height (looking straight down a line between centers). I wrote a spring calculator if you want to share that info but there are calculators online too. Exactly how much a rate change would affect the actual wheel rate would require more measurements and calculation. I don't know the details of the wide track mod. I assume the mod is lower control arms that move the coilover attachment outboard to maintain arm strength but reducing the effective ratio. Apples to oranges I know, but the standard S1 and S2 have rates around 95# front, 60# rear but the effective ratio of the coilover mounting is probably very different (higher effective ratio). If the chassis moves up over bumps instead of the suspension compressing, you may be giving up some road holding plus high rate springs can come off the seats in droop with no weight on the tire for traction. No more than a 10% rate change if any is what I'm suggesting.

-

Too bad it's not easy to take a 1/4 inch out of the trans mount so the engine could also be brought down a 1/4. There should be some clearance for engine movement under load. Funny to watch dyno runs of various machines and how much the engine flops about.

-

Cool running walk around of an S1 with Coventry Climax (sounds like a motorcycle). Interesting top mount slave cylinder, aluminum drum brakes all around and bias ply tires.

-

An oscillating tool is great for tight spots that a hack saw, band saw, or reciprocating saw can't reach. Works fine for cutting aluminum with the right blade. I use normal tools for the most part then a sonicrafter for the last little bit. All the major tool mfgs sell their own version these days.

-

If the wheel box location on your car is not closer to the windscreen vertical frame, the arms and blades are not longer, and the blades do not mount at a different angle on the arm, then the s3 gear should work. The gear determines the stroke from how far the link pin is off center, how far the spring moves back and forth in the tube, and ultimately how far the arm will swing back and forth. Hopefully the difference in spacing they were referring to is between the wheel boxes. It would help to know how many degrees the system is so you could make a template for minimum wheel box distance to the vertical frame.

-

The 2015 assembly guide for a 420 shows M8x40 cap screws to 20nm with nylocs. A 3/8 bit can cut the shoulder so you don't remove the paint trying to remove the insert of you want to go with 5/16 grade 8. If concerned about strength, use socket head screws or metric 12.9 or sae grade 8, partially threaded and a same grade nut.

-

I found in an early owners manual the motor described as "DR2" and having a self parking feature. This would be the single speed motor sourced from the pre-69 mini among other applications: https://www.minimania.com/part/GEU7714-DR2/Single-Speed-Wiper-Motor-Dr2-Mini--Morris-Minor-Less-Gear I think all the cats with a washer switch have an intermittent wipe relay box and two speeds.

-

Looks like it would be an on/off toggle, no self-park, not intermittent, and one speed. The gear stroke is probably less than a 115deg sweep. I'd work backwards from the appropriate wiper arm to determine the wheel boxes with the right pin type. Newer, more common motors with more functions could be used with just a toggle but the stroke could be critical with a fixed windscreen frame to wiper box distance. A three position toggle could provide two speeds. Self park just means operating it to allow it to park before installing the arms. Intermittent is a bit more complicated.