-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Articles

Gallery

Events

Library

Everything posted by JohnCh

-

Any updates? Did the head check out ok at the machine shop? -John

-

Congratulations to you both! Glad to see the car is staying in the USA7s family. -John

-

Fans of The Grand Tour/old Top Gear might appreciate the email I received late last week updating me on availability outside the UK. BTW @Vovchandr someone who works for me in the UK is a gin aficionado and has a bottle on order. I'll share her impressions once I have them. -John

-

Actually I wouldn't advocate for Emerald in this case. The easiest approach is the unlocked MBE which should be very close to plug and play and give added flexibility for future mods or diagnostics (data logging is great for this.) Given the number of Caterhams SBD works with, I'd hope they know if they assign the configurable pins differently than Caterham. That should be an easy change in the software. Did they say if the starter map is specific to a 420R engine or is it a generic map? -John

-

Call SBD to discuss the unlocked ECU. They carry a few unlocked MBE models and state they can supply starter maps as well as modified maps. Given you have a known and common configuration, they may have a map ready to go or very easy to modify. Worth a phone call to find out. https://www.sbdmotorsport.co.uk/ -John

-

My guess is that the L-shaped covers the area above and outboard of the carbon/stainless mudguard, whereas Large covers that complete area. I plan to leave the carbon mudguard in the box and use the bigger piece. -John

-

That looks like a lot of fun! I may need to research this more -John

-

Might be worth a call to SBD. They sell unlocked MBEs and they may have a 420R map available that works with a constant fuel pressure setup. -John

-

-

Have you examined the bores, valve springs, and valve seats yet? I know the color of the exhaust valves isn't a red flag, but it's interesting that the edges of pistons 2-4 on the exhaust side have matching discoloration. For the experts, does that point to an issue? -John

-

Did you remove the head this weekend as planned? If so, what did you find? Thanks, John

-

@fastg I think you mean this photo. Is that a reflection/optical illusion or is the top of that lobe damaged? -John

-

Do the dark black streaks wipe off or is the metal discolored? Get a quality dial indicator and holder. I've had the cheap stuff and discovered there was enough lateral play that readings done on an angle, like when setting cam timing, were not repeatable. -John

-

@Vovchandr not to create more angst, but are those lobes burnished or is that simply oil? Also, be careful of the aftermarket TDC bolts. I have two aftermarket versions for the Duratec and one from Ford. One of those aftermarket bolts is slightly off as confirmed with a dial indicator. The other two bolts are spot on. -John

-

ECU sets ignition timing. Cam timing, which determines when the valves are at full lift in relation to where the piston is in the cylinder, is mechanical. Call Web Cams on Monday to discuss the numbers you found and see if they can help. However, given the note in the build sheet about 3 cam combinations, it's possible that the intake is not from them as identified in the ECU. -John

-

Lining up the the slots on the back only works for the stock cams or aftermarket cams that were specifically ground with that setup in mind. The latter is not a standard (e.g. Kent, who is a major supplier of high spec cams for Zetecs and Duratecs, does not do this). Based on the ECU information, you have a stock exhaust cam and a Webcam intake. I've dealt with Webcam before after finding a pair of their cams in a used head. They keep good records and using the number engraved on the cams were able to find the specs for them even though they were a custom grind done many years earlier. Find the number, call them, get the specs to understand what you have. I'd also closely examine the exhaust cam to make sure that ECU notation is correct and they are stock. A challenge you face is not knowing exactly what the comments on the ECU info page really mean. Does "advanced intake and exhaust cams 5 degrees" mean 5 degrees from stock cam timing for both sides or from the specs provided by Webcam, or something else? Was that change based on a recommendation from an engine builder, the shop that supplied the cams, a guess, or established on the dyno? I'm a little (okay, a lot) anal. To be safe and to really understand the starting point, I would get a hold of a good quality dial indicator and holder and establish the existing timing before you release the cam belt. You will need these tools anyway when reinstalling the cams. Note: if your plan upon reassembly is to have the cam timing optimized on the dyno, then you could take accurate measurements of the slot angle of each cam and use this for reassembly rather than the dial indicator. It will be safe from the standpoint of valves meeting pistons and should be a good starting point for the dyno operator, provided that person is competent in that area -- that is not the case for all of them. -John

-

Road & Track just published an article about this epic journey: https://www.roadandtrack.com/car-culture/a37026916/ross-robbins-cross-country-lotus-elan/ -John

-

For some reason, some photos don't respond to the hack of rotating them in the native Windows Photo viewer. I had to use MS Paint, which did the trick. Now back to our regularly scheduled problem solving and upgradeitus programming... -John

-

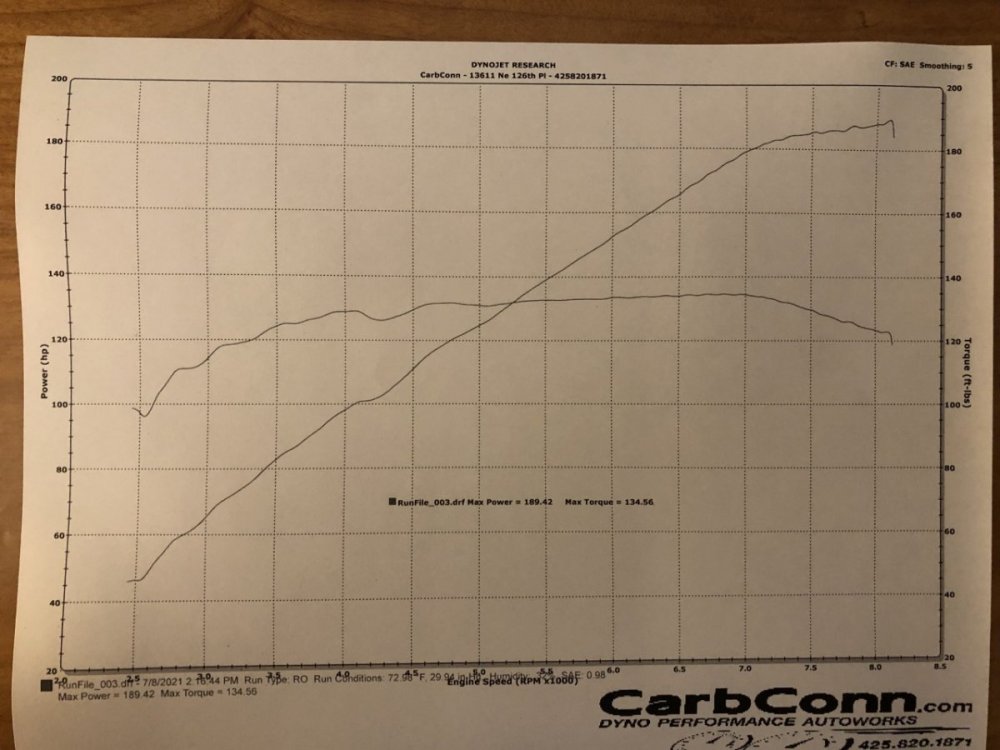

Thanks Andy. The shop with the hub dyno is the one I initially planned to use to dial in the engine -- the operator really seems to know his stuff -- but COVID restrictions made that tough. VRM filled the gap since my only concern at this stage was confirming timing at full throttle. Drivability/part throttle mapping was done on the road through logging and the Emerald's adaptive, closed-loop function and is fine, so VRM's lack of a load-based dyno wasn't an issue. However, for the new 2.4L engine in the Caterham, I won't have the luxury of a baseline map that is close and will have the hub dyno shop map that engine. Getting a baseline of my current engine on their dyno would allow an accurate comparison of the torque curves between the two engines. Unfortunately CarbConn has never met my expectations over the years, and this trip was no different. First, they didn't bother to clean the big pool of coolant and gearbox oil on the floor from a car that went earlier that day. On the surface, not a big deal, but to me it's a lack of attention to detail. How are you supposed to know if your car is dripping during the runs when the floor is like that? Second, the runs were all problematic. The fourth gear run had the sine graph issues. Not necessarily their fault, but annoying nonetheless. The next run in third gear was fine aside from the apparent wheelspin. During the next run, the engine stopped pulling at 6000rpm because they hadn't released the dyno brake (or at least that's what they told me) and on the fourth run, they forgot to hit record. I could have gone for a fifth run, but decided to cut my losses. It's a shame because they are the biggest facility in the area and have a recent 4 wheel Dynojet. -John

-

I'm not shopping for numbers. I was simply curious how the older VRM dyno would compare with the newer one at CarbConn. I didn't go to the latter first because I don't have confidence in their ability to tune a car based on prior experience, but I do have confidence in VRM. The reason I'm now considering the shop further away with a hub dyno is not to see if the numbers go up, but if my hypothesis about wheelspin is correct. Although I don't expect numbers to be the same from one dyno to another, I do expect the torque curves to have very similar shapes. That's not the case here and it makes me curious. -John

-

Looking more closely at the two dyno graphs as well as previous ones from a Mustang dyno with stock pistons and Kent DTEC10 cams vs. the new DTEC20 cams, I think I may know what's going on. The CarbConn graph is much flatter between 4300rpm and 7000rpm than the other graphs, and it doesn't peak until about 7000rpm vs. 5500rpm. Although I said there was no wheelspin during the third gear run, I'm wondering if there was a little? That would explain why the numbers on both graphs only differed by a couple of lb-ft at 4300rpm and 7000rpm, but the rise that happened between those two numbers in the other graphs were absent from the CarbConn results. Perhaps I was simply hitting the limit of torque the tires could transfer to the rollers during that range? The dyno operator at VRM could feel the wheelspin in third and I could see it while standing behind the car. At CarbConn, I was driving -- and have no experience doing dyno runs so easy for me to miss that slight sensation -- and no one was looking at the tires to confirm no slip. Judging by the seat of pants, the shape of the VRM torque curve also feels more accurate. There is a DynaPak hub dyno about an hour away. I may book time there to see what they show given their system eliminates the possibility of tire slip. -John

-

No idea. The torque doesn't feel less than the old engine with milder cams and lower compression ratio. That engine on a Mustang dyno registered 145 ft-lb, so consistent with the readings from VRM's dyno. Perhaps doing it in third gear lead to more parasitic losses than fourth gear which is 1:1, but that wouldn't explain the differences over 6700rpm. To me this simply shows that comparing dyno numbers gathered from different dynos is inconclusive. -John

-

Here is a picture that shows the pressure cap and thermostat housing so you can see how they work together. Regarding the tube in the overflow tank, it's best if the end is cut at an angle to ensure that it doesn't' seal against the bottom and prevent the flow of coolant under suction. -John

-

Hmm an (apparently) organized speed event with no helmet requirement. Must be a country with very few attorneys. -John

-

I took advantage of some downtime and booked a session at another dyno facility to compare their numbers to those achieved a couple of weeks ago at VRM. My assumption was this other facility, with a much newer Dynojet would produce higher numbers, but I was only partially right. Peak power was up to a bit over 189 vs. 184, but the entire torque curve was shifted downward except for the top end where it increased. In fact peak torque was fully 12 ft-lb lower today, but the torque falloff over 6700rpm was less severe, resulting in power increasing all the way to 8200rpm vs. flat from 6700-8000rpm in the original dyno session. Weather was nearly identical both days, the only differences were the Dynojet versions and the fact today's run was done in third gear vs. fourth at VRM. VRM tried third, but there was a lot of wheelspin. We tried fourth today, but the pull was taking too long and resulting in a really, really wavy trace that looked like a sine wave. Third gear today seemed wheelspin free. -John

.jpg.4b1dafeeade1799bf1afe87444adf874.jpg)